ATEX Fans are intended for use in equipment or protective systems where potentially explosive atmospheres can occur (as defined by EU directive 2014/34/EU). Mechatronics ATEX Fans are EC Fans (electronically commutated AC fans) made with encapsulated motors rated to IP68. ATEX Rating levels for Mechatronics fans are listed in the table below. Only fans with the ATEX symbol and rating on the label are intended for ATEX applications.

ATEX Fans are intended for use in equipment or protective systems where potentially explosive atmospheres can occur (as defined by EU directive 2014/34/EU). Mechatronics ATEX Fans are EC Fans (electronically commutated AC fans) made with encapsulated motors rated to IP68. ATEX Rating levels for Mechatronics fans are listed in the table below. Only fans with the ATEX symbol and rating on the label are intended for ATEX applications.| Series | Dimensions | Air Volume | ATEX Option Rating | ||

|---|---|---|---|---|---|

| mm | in | m3/min | CFM | ||

| LPT60B | 60 x 60 x 25 | 2.36 x 2.36 x 1.00 | 0.54 | 19.1 | EX II 3G Ex nA IIC Gc |

| LPT92A | 92 x 92 x 38 | 3.62 x 3.62 x 1.50 | 1.42 | 50 | EX II 3G Ex nA IIC Gc |

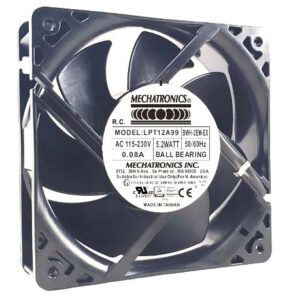

| LPT12A | 120 x 120 x 38 | 4.72 x 4.72 x 1.52 | 3.00 | 106 | EX II 3G Ex nA IIC Gc |

| LPH12A | 120 x 120 x 38 | 4.72 x 4.72 x 1.52 | 2.44–3.51 | 86–124 | EX II 3G Ex ec IIC Gc |

| LPH12A-5 | 120 x 120 x 38 | 4.72 x 4.72 x 1.52 | 2.18–3.91 | 77–138 | EX II 3G Ex ec IIC Gc |

| LPT15P | 172 x 152 x 51 | 6.77 x 5.98 x 2.03 | 6.23 | 220 | EX II 3G Ex nA IIC Gc |

| LPT25G | 254 dia x 89 | 10.00 dia x 3.50 | 14.44–23.22 | 510–820 | EX II 3G Ex nA IIC Gc |

| Mechatronics ATEX Certification & Label Markings | |

|---|---|

| Explosion Protection | EX |

| Equipment Group | Zone II |

| Equipment Category | 3 |

| Atmosphere | G |

| Equipment Protection | EX ec (increased safety) EX nA (non-sparking) |

| Gas Group | IIC |

| Equipment Protection | Gc |

What is ATEX and where are ATEX rated fans used?

Special electric components are required for environments where explosive gasses, vapor-air mixture, or combustible dust is possible in concentrations high enough to cause explosions. ATEX directives were adopted to align the technical requirements for products intended for use in potentially explosive atmospheres. Mechatronics ATEX rated products comply with the directives. All Mechatronics ATEX rated fans are marked with ATEX symbols and markings that indicate protection level and conformity with the directive. The ATEX directives not only define product requirements, but also classify environment zones and equipment categories. For more information on ATEX Directives, Ratings, and certifications visit the European Commission website for ATEX.

What is an EC Fan and why is it used in applications requiring ATEX?

Mechatronics electronically commutated (EC) technology fans converts AC power to DC power internal to the fan, so Mechatronics EC fans can be installed anywhere a similar sized AC fan is used. Energy saving EC fan technology is used to make ATEX fans because the design allows for coating or complete encapsulation of internal electrical components connections and the fan motor winding. Mechatronics UL recognized EC fans with ATEX rating are available in frame sizes from 60mm-172mm, with models compatible with input voltages from 100-240VAC. Mechatronics EC fans come standard with terminal type plugs or lead wires for simple replacement of less efficient AC fans in existing applications.

What is Encapsulation, and why choose this type of ATEX fan?

ATEX Fan Applications

- Commercial Refrigeration

- Air Conditioning

- Battery Compartments

- Food Processing Equipment

- Freezers & Icemakers

- Heat-Pump Dryers

- Water Heaters

- Industrial Refrigeration

- Chemical Storage

- Oil and gas equipment

- R290 propane and other flammable refrigerants

- LPH12A99 ATEX Certificate

- LPT15P ATEX Certificate

- LPT60B99 ATEX Certificate

- LPT12A99 ATEX Certificate

- LPT92A99 ATEX Certificate

For more information about ATEX rated fans available from Mechatronics, contact your local sales representative or request information through our online Engineering Contact Request Form.

For more information about ATEX rated fans available from Mechatronics, contact your local sales representative or request information through our online Engineering Contact Request Form.