Motorized Impellers

Mechatronics AC & DC Backward Curved Motorized Impellers offer exceptional airflow and pressure performance with a variety of voltage, speed control, alarm output, and environmental protection options. Standard impeller models are available from 120mm-400mm diameter. Please contact Mechatronics with your engineering requirements. Mechatronics engineers are available to assist with development of custom cooling solutions to meet the demands of your application.

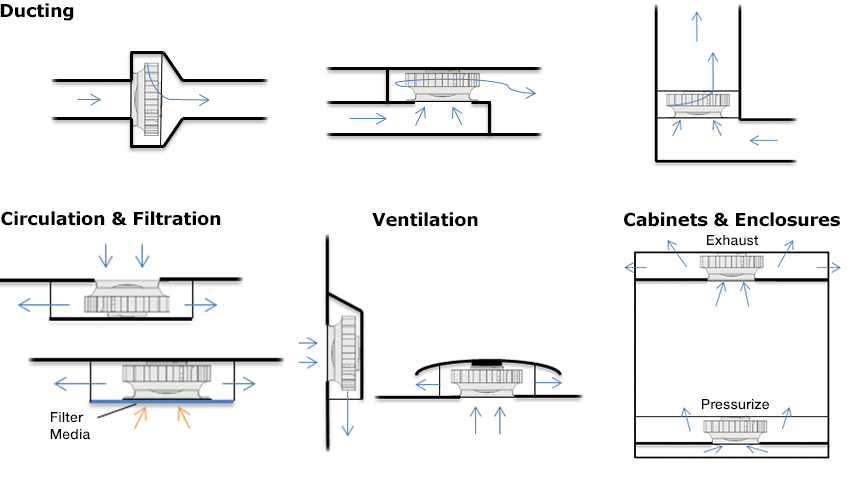

Typical Impeller Installations

DC Motorized Impellers General Specifications*

- Aluminum die cast motor base

- Nylon or metal impeller

- High precision chrome steel ball bearings

- Voltage Speed Control and Tachometer Output

- Class A motor insulation (unless otherwise noted)

- 12VDC, 24VDC, and 48 VDC

- Soft Start & Auto Restart

- Operating temperature range: -10 ~ 70 degrees C

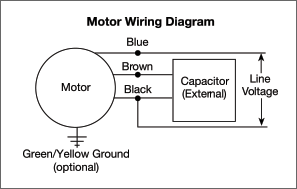

DC Motorized Impeller Connection Reference

AC Motorized Impeller General Specifications*

- Aluminum die cast motor base

- Nylon or metal impeller

- High precision chrome steel ball bearings

- 115VAC, 230VAC or 115/230VAC dual voltage

- Thermal Protection

- Class B motor insulation (unless otherwise noted)

- Operating temperature range: -20 ~ 50 degrees C

- Dielectric strength: AC 1500V (50/60Hz) for one minute

* Actual specifications, tolerances and safety agency approvals vary by model. Consult Mechatronics for individual specifications.

AC Motorized Impeller Options

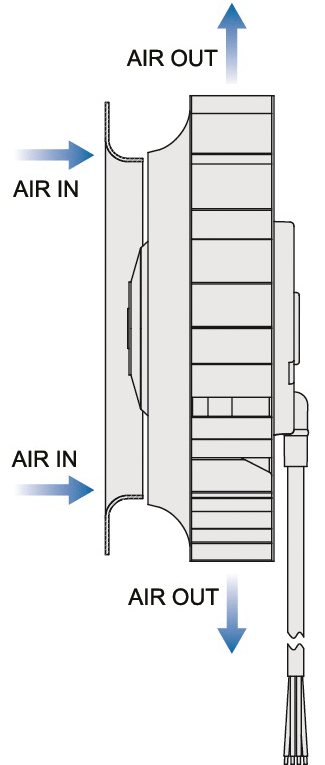

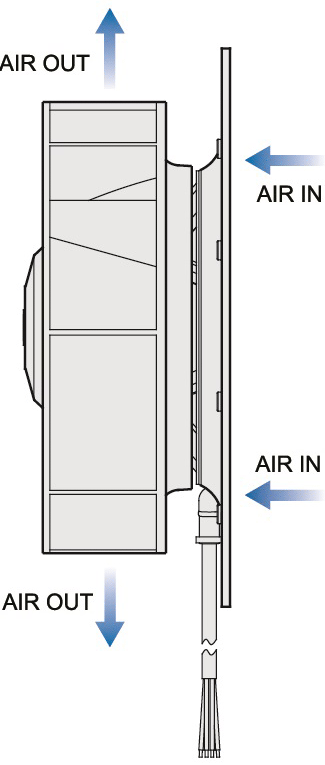

Mechatronics offers the standard motorized impeller package as well as a unique configuration which combines the impeller and inlet ring in one complete package. The integrated inlet ring doubles as a mounting plate.

|

Standard motorized impeller integration requires an inlet ring to block the exhaust air from re-entering the air intake. For optimal performance, the inlet ring must be mounted to an adjacent surface aligning it with the impeller intake. |

|

Mechatronics integrated inlet ring option eliminates the need for an additional adjacent surface for an inlet ring. Simply mount the device and power it up. This simplifies integration as well as reduces your assembly labor time. |